Products

Integrating SWCNTs with MEMS technology

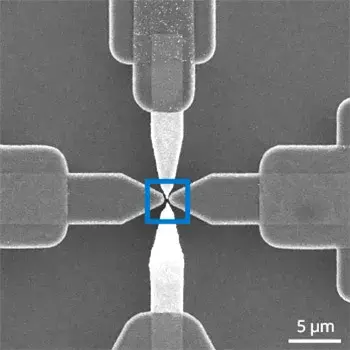

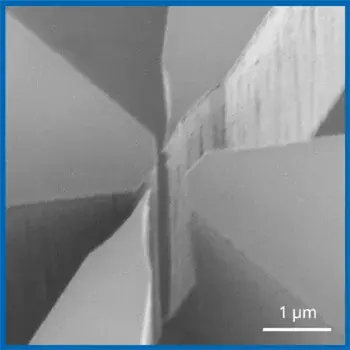

MEMS structures were fabricated using the Bosch Process to integrate field-effect transistor (FET) with single-walled carbon nanotubes (SWCNTs).

Terminals (source, drain and gate) were separated with sub-micron gaps by the anisotropic etch process.

Photo courtesy of Tabata/Tsuchiya Lab, Kyoto University.