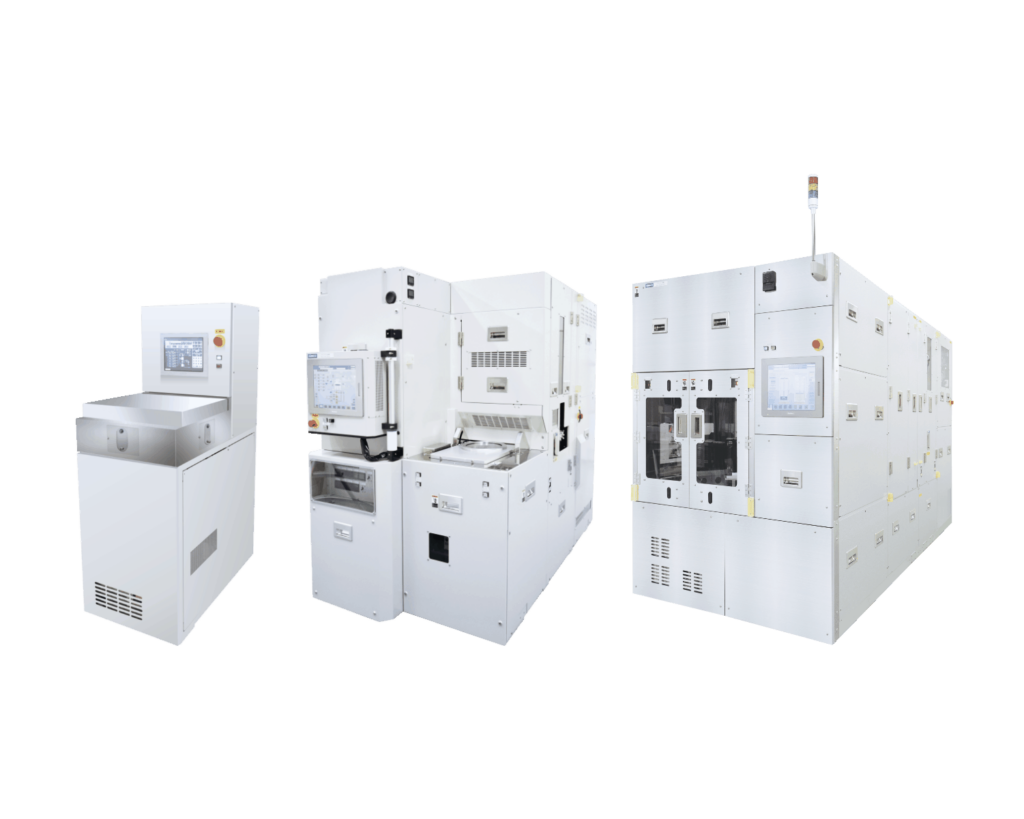

Since our establishment in 1979, Samco Inc. has developed a wealth of enabling technologies in deposition, etching, and surface treatment, driving cutting-edge research and device production. We offer a variety of advanced manufacturing equipment, including precise thin film deposition systems like Atomic Layer Deposition (ALD), Cathode-coupled Plasma Enhanced Chemical Vapor Deposition (PECVD), and Anode-coupled PECVD. Our high-performance etching systems, such as Atomic Layer Etching (ALE), Inductively Coupled Plasma (ICP), Deep Reactive Ion Etching (DRIE), Reactive Ion Etching (RIE), and Xenon Difluoride Etching, support a wide range of etching applications in semiconductor device fabrication. Additionally, our Cleaning Systems, including Aqua Plasma® Cleaners, Plasma Cleaning Systems, and UV Ozone Cleaners, are effective solutions for removing organic contaminants and surface modifications. Whether you need a top-notch R&D system or a production worthy system, Samco has innovative solutions to meet your needs from lab to fab.

Deposition Systems

Our deposition solutions include a variety of high-performance systems designed for precision and versatility:

- Atomic Layer Deposition (ALD)

- Anode PECVD

- Cathode PECVD

Etching Systems

Samco provides an array of advanced etching solutions, backed by process expertise and tailored support:

- Atomic Layer Etching (ALE)

- Inductively Coupled Plasma (ICP) Etching

- Silicon Deep Reactive Ion Etching (Si DRIE)

- Reactive Ion Etching (RIE)

- Xenon Difluoride (XeF2) Etching

Surface Treatment Systems

Our advanced dry cleaning systems use gas-based processes to overcome limitations of wet chemical cleaning:

- Aqua Plasma® Cleaners

- Plasma Cleaning Systems

- UV Ozone Cleaning Systems