Si DRIE (Deep Reactive Ion Etching) for MEMS and TSV

SAMCO Inc. > Featured Solutions > Si DRIE for MEMS and TSV

The Bosch Process

Samco was the first Japanese semiconductor process equipment manufacturer to offer Deep Reactive Ion Etching (DRIE or Deep RIE) systems using the Bosch Process for MEMS and TSV fabrication.

The Bosch Process is a high-aspect ratio etching technology, which repeats the cycle of isotropic etching followed by protection film deposition. The SF6 plasma cycle etches silicon, and the C4F8 plasma cycle creates a protection layer. Combining this process technique with our latest system technology has produced industry leading results for both research and manufacturing customers.

Samco’s Process Capabilities

Smooth Sidewalls Process

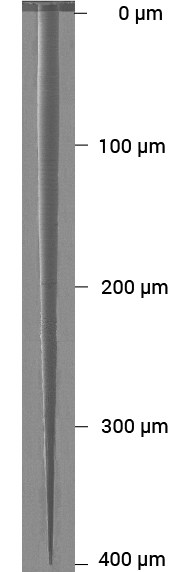

Ultra Deep Tapered Etching

This 400 µm deep tapered profile (ø 15 µm) was fabricated with process optimization. The profile shows aspect ratio of 27, and tilt is controlled within 90 ° +/- 0.3 ° .

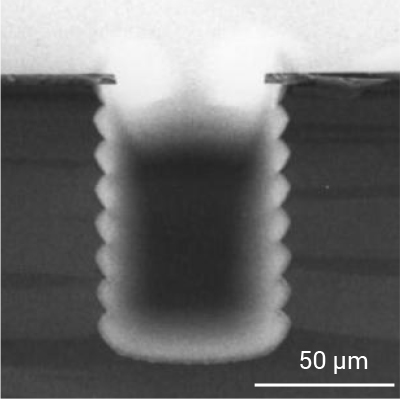

High Etch Rate

The pattern width is 50 µm.

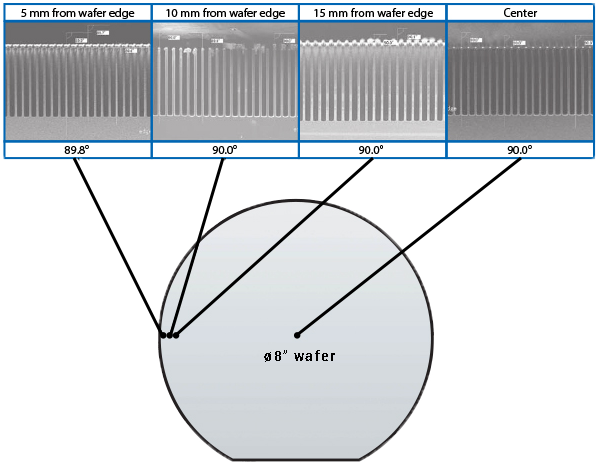

Tilt Free Process

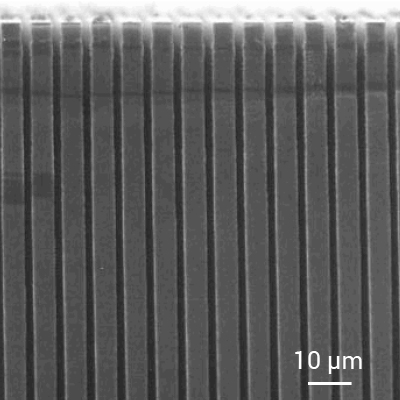

High Aspect Ratio

Aspect ratio of 40 is achieved.

(pattern width: 2.5µm, etch depth: 100 µm)

In this process, the scallop size is controlled to less than 100 nm.

Notch Free Silicon On Insulator (SOI) Etching

The standard Bosch Process causes undesirable notching at the silicon/insulation interface due to electrical charging. Samco has developed a unique notch-free SOI etching process that maintains the etch selectivity by using superimposed Radio Frequency (RF) power.

The Value of Samco’s Processes

Breaking the challenges in device fabrication

Breaking the challenges in device fabrication

Samco’s DRIE processes have achieved the most challenging process goals of our customers.

Throughput enhancement with repeatable process

Throughput enhancement with repeatable process

Samco’s process repeatability shows significant benefits for production in which quality & reliability management is critical.

Easily scalable from R&D to high-volume production

Easily scalable from R&D to high-volume production

Samco offers multiple DRIE systems depending on the customers’ requirements.

Samco DRIE Systems

Samco provides multiple DRIE systems for both R&D and production.

RIE-400iPB

processing up to ø4”wafers

RIE-800iPB

processing up to ø8”wafers

RIE-800iPBC

processing up to ø8”wafers