Silicon Carbide (SiC)

Silicon Carbide (SiC), one of the compound semiconductor materials, has unique material properties. For example, it has high electrical breakdown strength (ten times that of Silicon) and thermal conductivity (three times that of Silicon). These properties are attracting more attention of researchers and engineers. One of the most promising applications of SiC is power devices used in electronics. While Silicon-based power devices currently dominate the market, these devices have limits of their breakdown voltage. On the other hand, due to the electrical breakdown strength of SiC, SiC power devices allows high-efficiency power conversion without breakdown. Potential growth of the SiC power devices is expected to be huge in markets such as automotive, trains and aerospace in which the devices need to operate in high-voltage and high-temperature.

Challenges in SiC Power Device Fabrication

One of the challenges in SiC power device fabrication is the material quality of the SiC substrate. Micropipe defects formed during epitaxial growth of the SiC substrate deteriorate breakdown voltage. Therefore, the defects lead to the low device reliability and limit the industrial use of the devices. For the device fabrication process, there are some challenges in the SiC dry etching process, specifically in the trench type metal–oxide–semiconductor field-effect transistor (MOSFET) fabrication.

1. Etch profile control

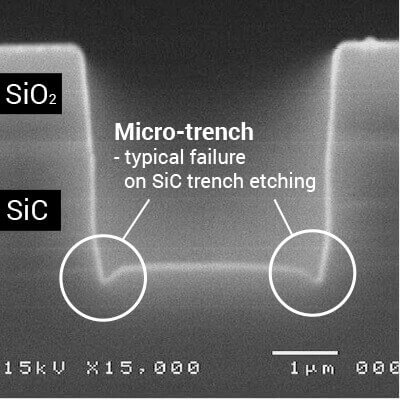

Micro-trenches and surface roughness on trench sidewalls after etching cause a gate oxide breakdown with the concentration of electric fields on the bottom. The gate oxide breakdown causes lower breakdown voltage of the device.

2. Low etch rate

Due to its physical hardness and chemical stability, etch rate of SiC is relatively low, and it limits process throughput.

3. Low etch selectivity over etch mask

A thick Silicon Oxide (SiO2) film is required for SiC etching due to low etch selectivity.

Samco has developed systems and processes specialized for SiC power device fabrication to meet our customers’ severe requirements. The following highlights Samco’s SiC trench etching technologies for SiC trench type MOSFET fabrication.

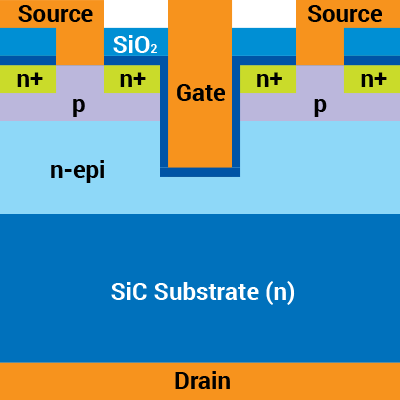

Structure of SiC trench type MOSFET

SiC trench profile fabricated using a conventional etch process

Samco’s Process Capabilities

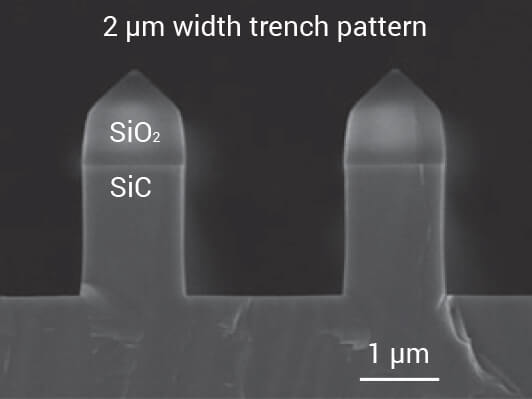

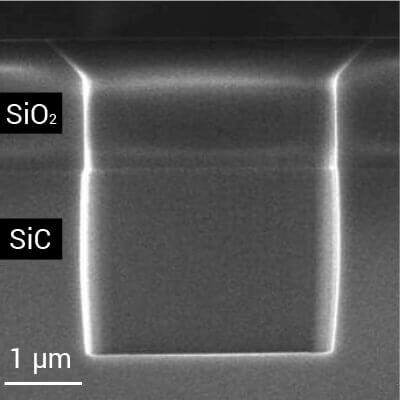

Micro-trench Free Profile with Smooth Sidewalls

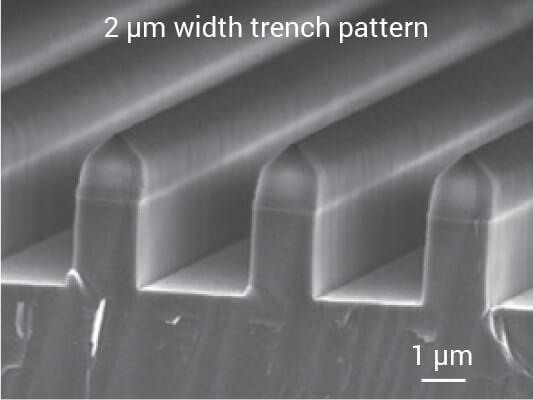

A 2 μm deep trench profile (2 μm width) is fabricated. With an adjustment of electrode gap and bias power, the micro-trench is removed, and the sidewall shows a smooth surface.

High Etch Rate

With an adjustment of the ICP and bias power, an etch rate of over 700 nm/min is achieved.

High Etch Selectivity Over SiO2 Mask

A selectivity of over 13:1 (SiC/SiO2) is possible with pressure optimization.

Cross-section SEM of an optimized etch process

Etch Rate: 775 nm/min

Etch Selectivity (SiC/SiO2): 13.4

The Value of Samco’s SiC Etch Processes

Breakdown voltage improvement

Samco’s processes have contributed to the development of industry-leading high-performance SiC power devices.

Throughput enhancement with repeatable process

Samco’s systems are designed to be durable even when severely used in both R&D and production lines.

Reduction of SiO2 mask fabrication cost

Combining etch with PECVD technologies, Samco offers turn-key solutions for low-cost fabrication of high-performance SiC power devices.

Samco ICP Etch Systems for SiC Etching

Samco has developed an ICP system for etching hard materials such as Silicon Carbide (SiC).

The RIE-800iP and RIE-800iPC produce high SiC etch rates with excellent profile control.

RIE-800iP

processing up to ø8”wafers

The Samco RIE-800iP is an ICP (Inductively Coupled Plasma) etching system capable of generating a high density plasma. The system includes a ICP Reactor chamber, and a Load Lock. The RIE-800iP features a high conductance vacuum system coupled with precise pressure control to allow processing at both low and high pressures. A high-power Tornado ICP coil maintains a stable plasma at higher RF powers. Together, these features provide users with the widest process window available.

RIE-800iPC

processing up to ø8”wafers

The Samco RIE-800iPC is the cassette version for SiC power device production. The standard system includes a ICP reactor chamber, a transfer chamber with robot, and a Vacuum Cassette with elevator. Additional options are available for full factory automation.

System Features

Unique and Optimized ICP Coil

Newly developed ICP coil allows high-density stable plasma discharge at low pressure for high-speed SiC etching.

High-conductance Vacuum Pump

High-conductance vacuum pump enables SiC etching at both low and high pressures, and low and high gas flows.

Height-adjustable Electrode

Height-adjustable lower electrode (air operated) enables optimization of the distance between the wafer and ICP plasma source.

Designed for Easy Maintenance

Movable Turbo Molecular Pump (TMP) unit shortens maintenance operation time.

Cassette and Robot Handling

Samco offers both R&D and production models ,and easily expandable from R&D to production.