GaAs ( Gallium Arsenide) Etching

Samco’s GaAs etching technology provides precise, high-uniformity plasma dry etching essential for fabricating VCSELs, laser diodes, MicroLEDs, RF devices, and photonic structures. Our ICP-RIE systems enable excellent profile control, stable etch performance, and accurate endpoint detection across wafer sizes up to 6 inches.

With decades of experience in III-V etching, Samco supports both production environments and advanced research laboratories worldwide.

Why GaAs? Material Properties and Key Applications

Gallium arsenide (GaAs) is a III-V semiconductor with:

- Band gap: 1.27 eV

- Electron mobility: 8,500 cm²/V·s (5.7x higher than Si)

These properties make GaAs ideal for:

- RF and MMIC devices (power amplifiers, oscillators, switches)

- Laser diodes (LDs) and VCSELs

- Infrared LEDs

- High-efficiency solar cells

- Photonic and quantum devices

GaAs Etching Benefits & Performance

High Uniformity Across 6-Inch Wafers

Our ICP-RIE systems maintain excellent uniformity for GaAs mesa and trench etching. Optional interferometry endpoint detection ensures high-accuracy etch stops even for multi-wafer processes.

Etch Profile Control, Selectivity, and Damage Reduction

Samco’s ICP-RIE systems are optimized for precise GaAs etch profiles, enabling:

- Steep, vertical sidewalls for VCSEL and FET structures

- High etch rates suitable for deep mesa and trench applications

- Low byproduct redeposition for smooth surfaces

- High selectivity between GaAs and mask materials (photoresist, SiO₂)

- Stable profile control across wafer sizes up to 6 inches

These capabilities support the performance demands of modern optoelectronic and RF devices.

GaAs Etching Process Data

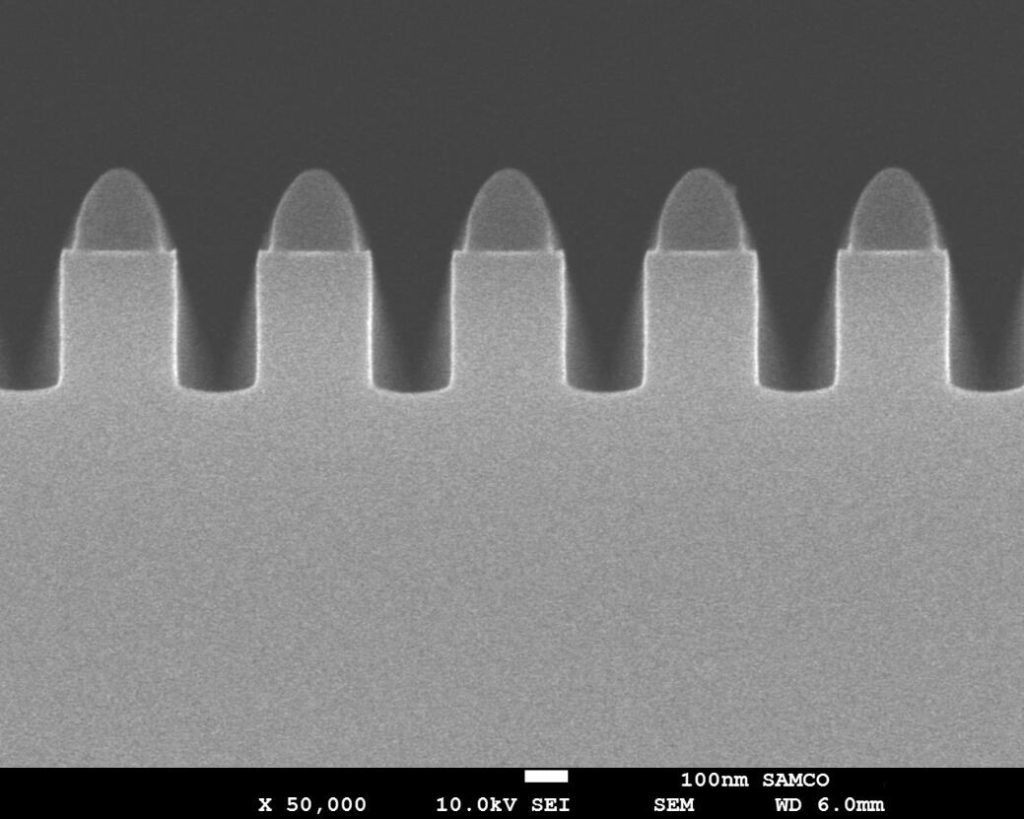

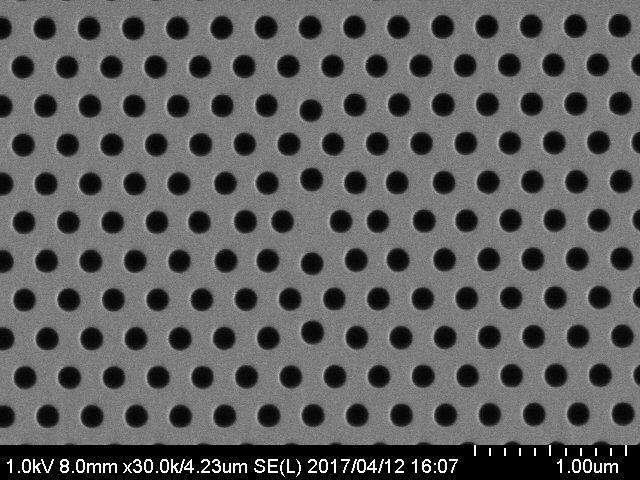

By replacing the upper DBR of the active layer with a diffraction grating, it is possible to improve the performance of the VCSEL.

Products

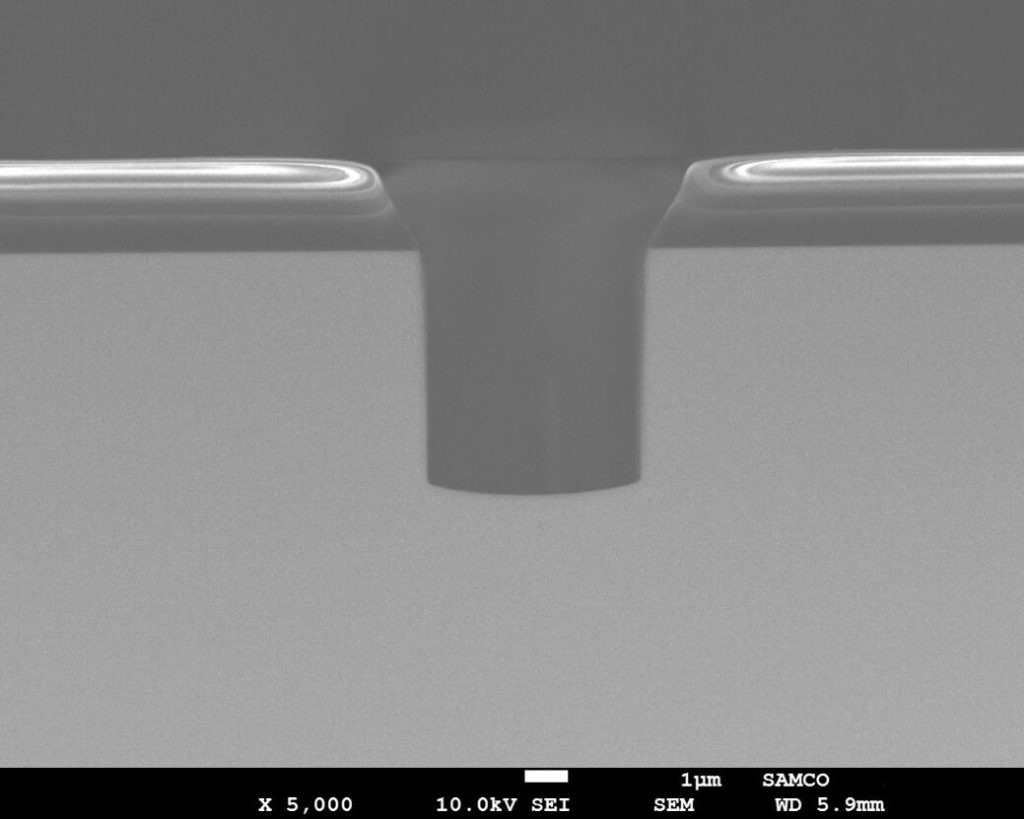

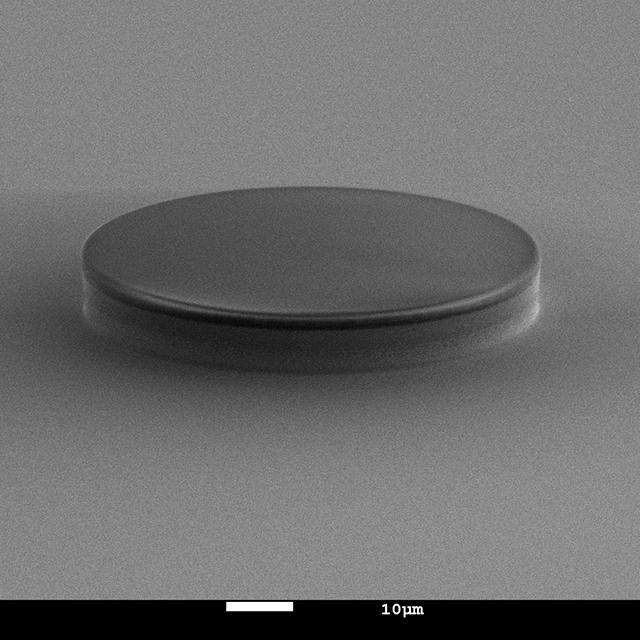

Our process technology enables high-speed vertical machining up to and including ø6 inch wafers. This shows an example of a GaAs mesa etching process with an etching rate of about 2 μm/min.

Products

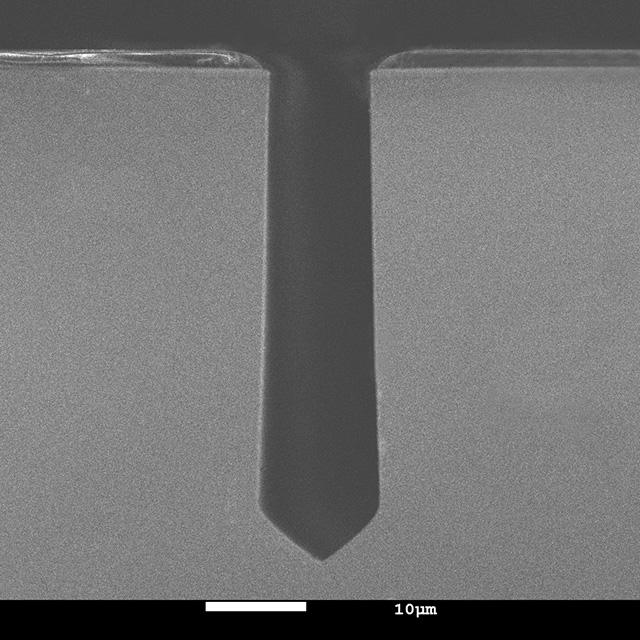

This shows an example of vertical mesa etching on a ø3 inch VCSEL (Vertical Cavity Surface Emitting Lasers) wafer.

Products

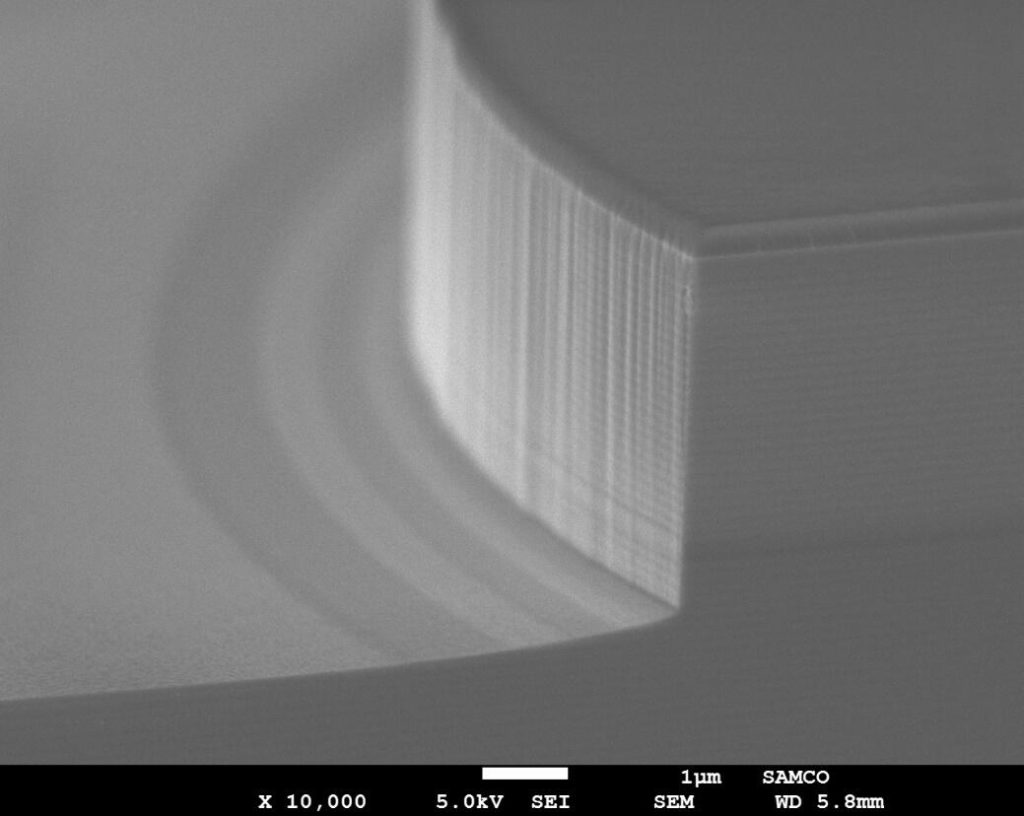

Achieved 3.8 μm deep GaAs etching with <±5% uniformity across ø6-inch wafers, ensuring precise and consistent results for MicroLED fabrication.

Products

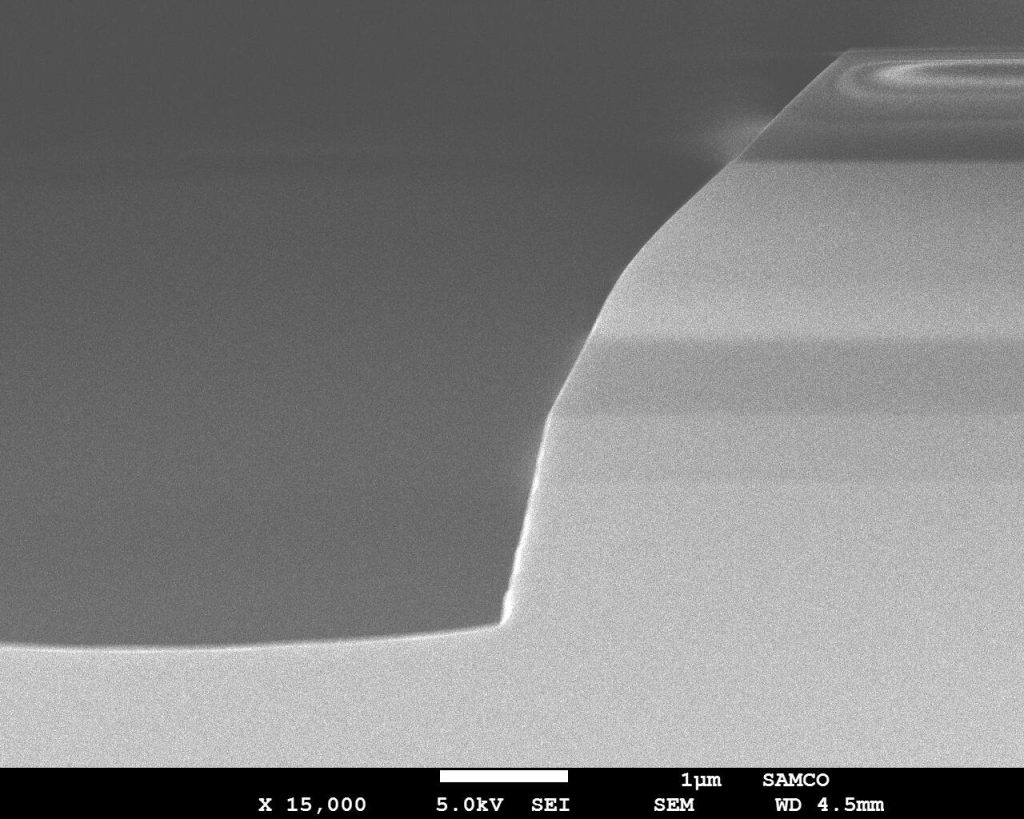

The system of semiconductor quantum dots coupled with nano-resonators is expected to be applied to quantum photonics devices and quantum information devices.

Products

Fine anisotropic etching VCSEL (Vertical-Cavity Surface-Emitting Laser) is a semiconductor laser whose resonance direction is perpendicular to the substrate surface.