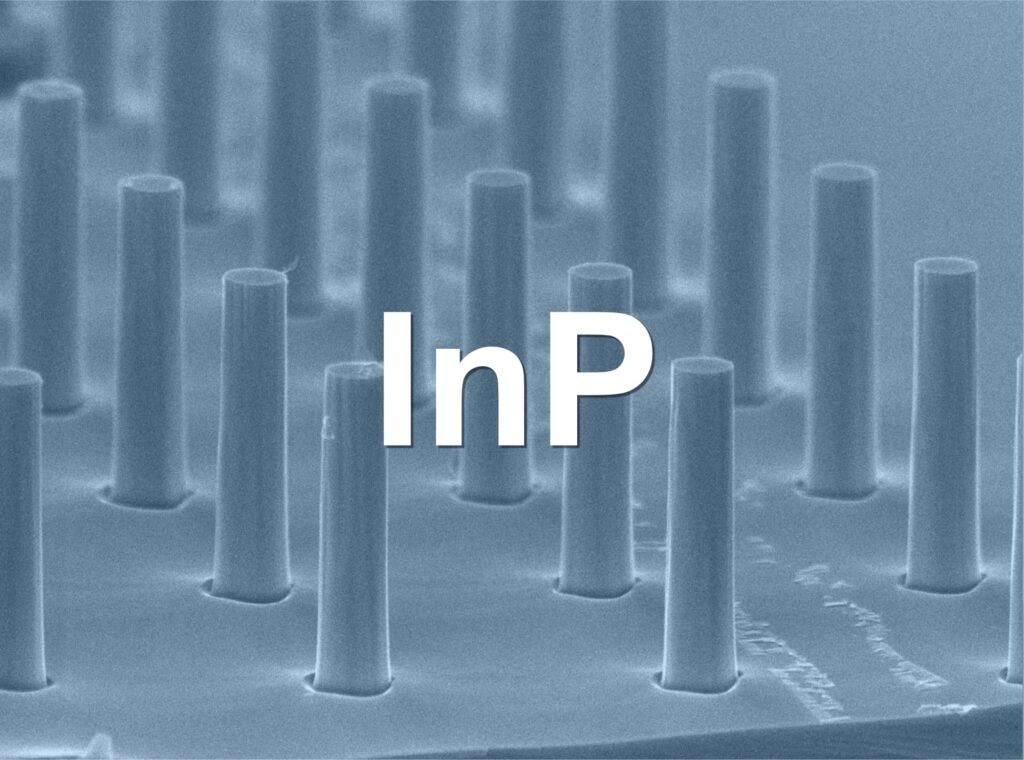

Indium phosphide (InP) etching

Indium Phosphide (InP) is a key III–V semiconductor used in high-speed photonics, telecommunications, infrared devices, and advanced RF applications. Because InP forms non-volatile etch byproducts, controlling sidewall angles and suppressing polymer redeposition are critical challenges in plasma dry etching.

Samco provides advanced ICP-RIE etching solutions engineered to achieve vertical profiles, smooth surfaces, and highly accurate dimensional control for InP-based devices. With decades of III–V process expertise, our systems deliver reliable results for both R&D and volume manufacturing.

Why InP? Material Properties and Key Applications

InP is distinguished by its excellent electrical and optical properties:

- Band gap: 1.35 eV

- Electron mobility: 5,400 cm²/V·s (300 K)

- Large lattice constant: ideal for InGaAs, InGaAsP, AlInAs, and AlGaInAs heterostructures

These characteristics make InP the foundation of:

- High-speed laser diodes (LDs)

- Photodiodes and high-power photonic devices

- Waveguides and integrated photonic circuits

- RF and microwave devices requiring low noise and high gain

- High-efficiency photovoltaic and nano-optic structures

Because many InP-based structures require vertical pillars, gratings, ridges, or deep waveguide features, high-quality anisotropic plasma etching is essential.

Advanced Plasma Etching for InP Devices

Samco’s ICP-RIE technology is optimized to address the unique challenges of InP etching:

- Stable profile control despite complex InP etch chemistries

- Suppression of byproduct redeposition, enabling straight sidewalls

- High etch uniformity across small- and large-diameter substrates

- Fine control of sidewall angle and bottom surface roughness

- Low-damage processing suitable for photonic devices and optical cavities

These capabilities support applications ranging from laser diode ridge formation to nanopillar arrays and photonic crystals.

InP Etching Benefits & Performance

Vertical Sidewalls & Profile Stability

InP etching often suffers from rounded or tapered sidewalls due to non-volatile etch residues. Samco’s optimized ICP configurations minimize polymer deposition and enable highly anisotropic etching for pillars, waveguides, gratings, and resonator structures.

Smooth Surfaces for Optical Performance

Controlling surface roughness (RMS) is critical for high-performance LDs and photonic crystals. Samco’s process conditions maintain smooth surfaces on both sidewalls and trench bottoms, improving optical confinement and reducing propagation losses.

High Etch Rates with Excellent Selectivity

Our InP etch processes deliver:

- High etch rates suitable for deep features

- Strong selectivity to SiN, SiO₂, and other hard masks

- Repeatable profile control across varied device geometries

These benefits support both fabrication flexibility and high device yield.

InP Etching Process Data

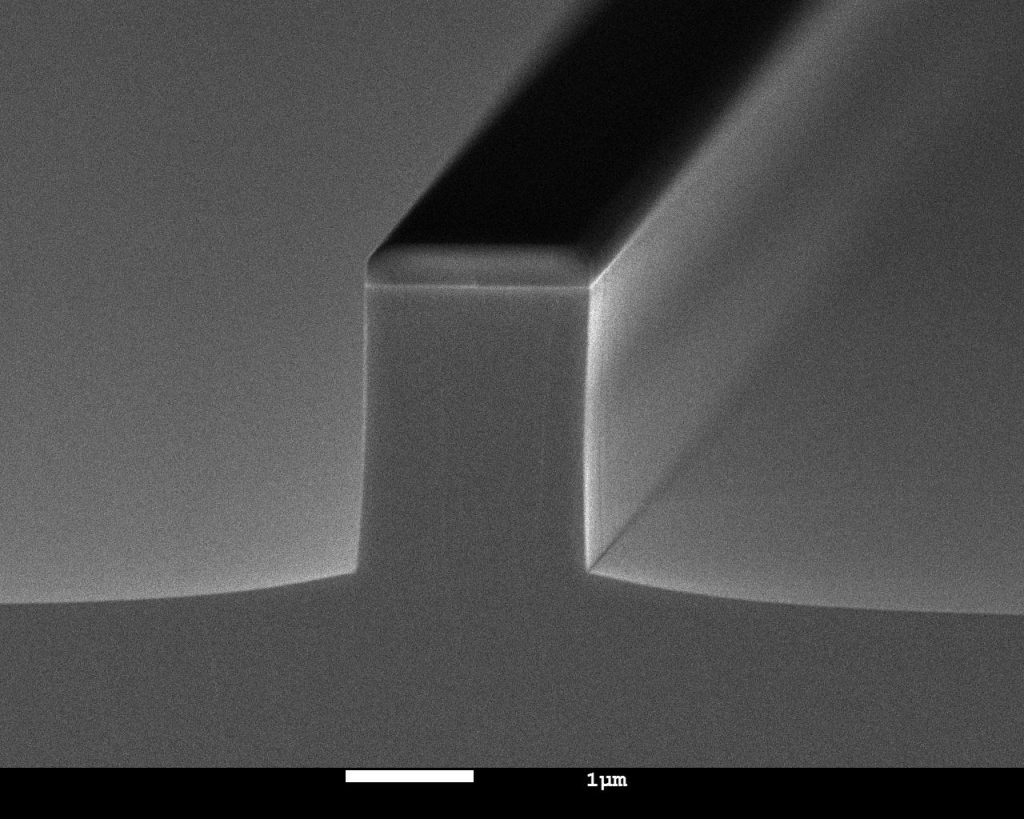

The anisotropic and small footing ridge shape with a width of 1.8 μm and a depth of 2.5 μm has been achieved.

Products

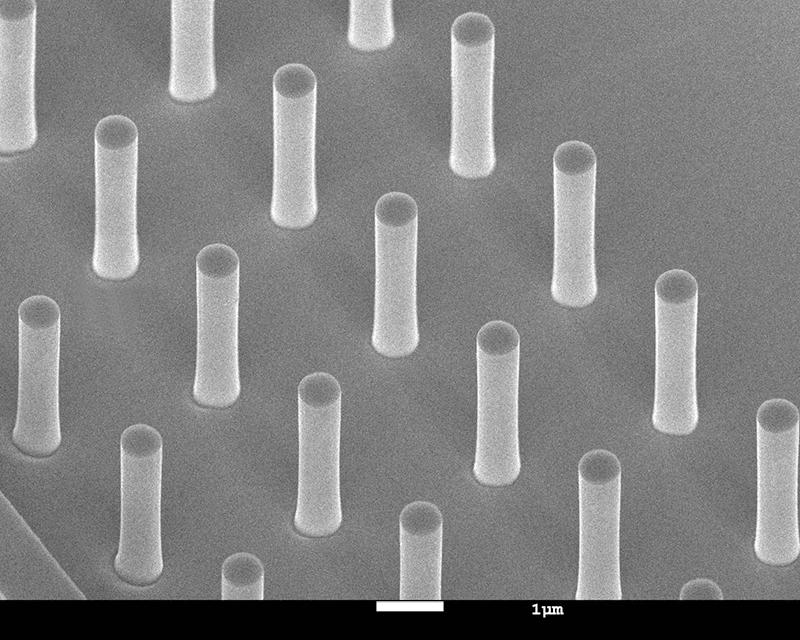

This process can be applied to semiconductor lasers and photonic crystals. A smooth pillar, 0.7 µm in diameter and 4 µm deep, with vertical, no sidewall or bottom roughness, has been formed.