Introduction

Atomic Layer Deposition (ALD) is a technique that enables the formation of thin films at the atomic scale through the alternate supply of two different precursors. ALD is well known for its excellent surface coverage and in-plane thickness uniformity[1] [2]. It has been widely adopted to enhance chemical and moisture resistance, as well as to introduce functional optical properties. In such applications, uniform deposition may be required not only on the front surface of the wafer but also on the back surface and edges.

Traditional film deposition techniques such as Plasma Enhanced Chemical Vapor Deposition (PECVD) and sputtering generally require separate process cycles to coat both surfaces of a wafer. This repetition can negatively affect process efficiency and reproducibility. In contrast, the superior conformality of ALD allows for dual-surface film formation in a single cycle. Although previous studies have demonstrated simultaneous deposition using thermal ALD, reports involving Plasma Enhanced ALD (PEALD) remain limited.

This report describes the successful simultaneous dual-surface deposition of AlOx thin films on silicon wafers using a direct plasma-based PEALD process.

Experimental Conditions

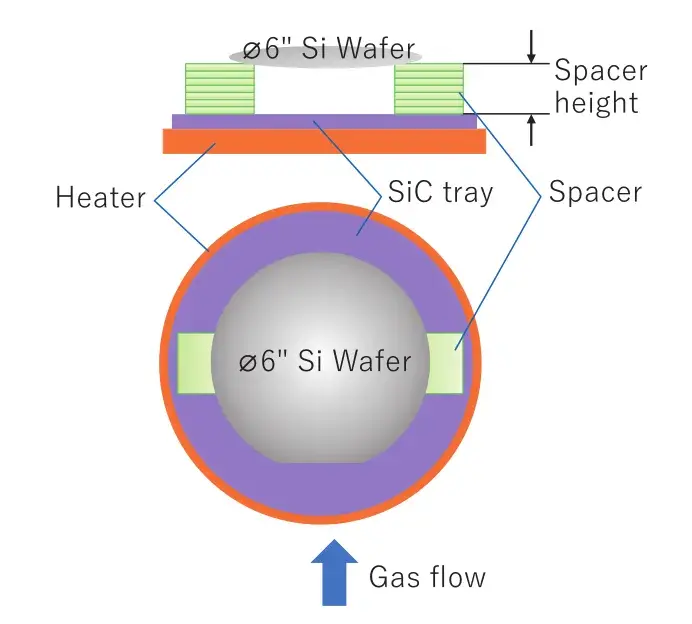

This study examined the feasibility of simultaneous dual-surface film deposition on silicon wafers using the Plasma Enhanced Atomic Layer Deposition (PEALD) technique. Double-side polished 6-inch Si wafers were suspended within the reaction chamber using spacers, as illustrated in Figure 1. Trimethylaluminum (TMA) was employed as the aluminum precursor, and oxygen was introduced in plasma-enhanced mode as the oxidant. The substrate temperature was maintained at 300 °C, and the gas flow was oriented horizontally.

To evaluate deposition characteristics, film thickness distributions on both the front surface and back surface of the wafer were measured. Spacer heights of 7 mm, 11 mm, and 14 mm were tested to determine their influence on thickness uniformity.

Results and Discussion

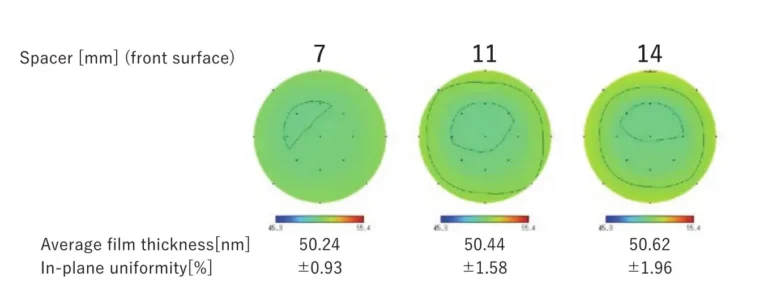

As shown in Figure 2, ellipsometry measurements of the front surface revealed no significant variation in average film thickness across the three spacer heights.

When the spacer height was varied to 7 mm, 11 mm, and 14 mm, no significant fluctuation was observed in the average film thickness. A slight increase in thickness near the wafer edge was noted; however, in-plane uniformity remained within ±2%, indicating excellent reproducibility.

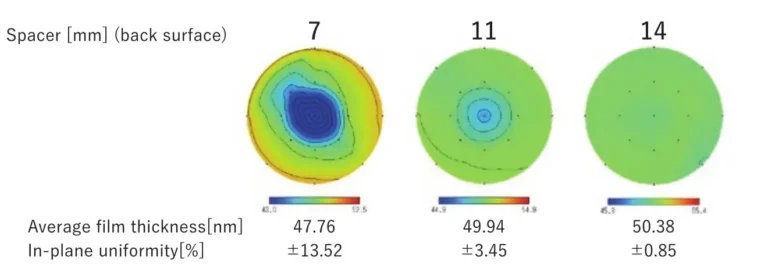

In contrast, the back surface results shown in Figure 3 exhibited clear improvements in both average thickness and in-plane uniformity with increasing spacer height.

A consistent pattern of central thinning and edge thickening was observed, suggesting limited plasma radical transport to the center of the wafer.

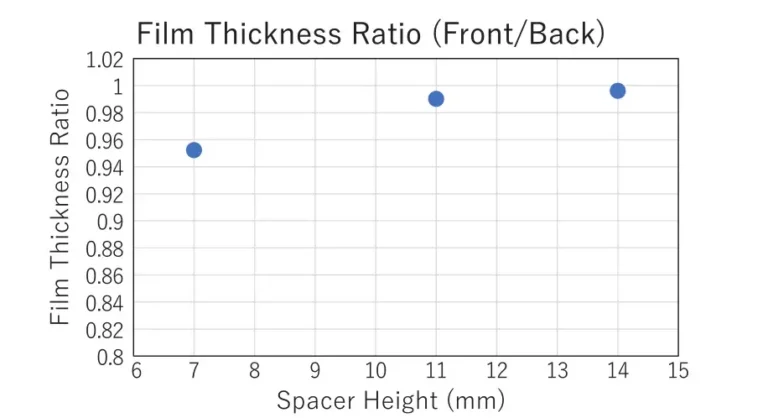

Figure 4 presents the ratio of back surface-to-front surface film thickness. As spacer height increased, the ratio approached unity, reaching 0.99 at 14 mm. This indicates nearly equivalent deposition on both surfaces.

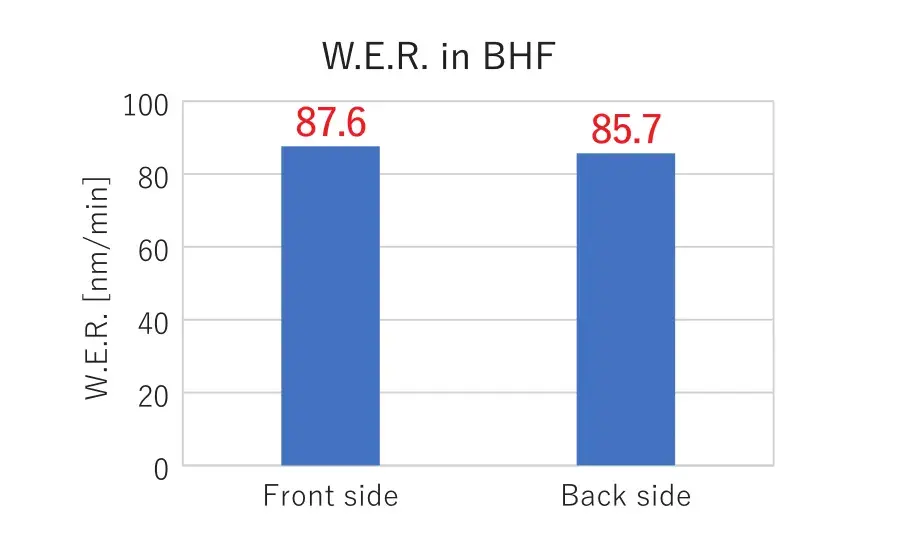

Further analysis of the AlOx films deposited under the 14 mm condition showed refractive index values ranging from n = 1.705 to 1.712 on both surfaces. Wet etch rate (W.E.R.) testing with respect to buffered hydrofluoric acid (BHF) yielded rates of 87.6 nm/min on the front surface and 85.7 nm/min on the back surface, confirming the uniformity of film composition and structure.

These results collectively demonstrate that a spacer height of 14 mm enables highly uniform dual-surface deposition in both film thickness and material quality.

Conclusion

This study investigated a method for simultaneous dual-surface deposition of AlOx films on silicon wafers using the Plasma Enhanced Atomic Layer Deposition (PEALD) technique, in which wafers were suspended within the chamber using spacers. Spacer heights were varied between 7 mm and 14 mm. The results indicated that increasing the spacer height led to a reduction in thickness differences between the front surface and back surface. At a height of 14 mm, the film thickness ratio reached 0.99, demonstrating nearly equivalent deposition on both surfaces.

Furthermore, under the 14 mm condition, the refractive index and wet etch rate measurements revealed negligible differences between the front surface and back surface. These findings confirm that uniformity was achieved not only in film thickness but also in film quality.

Future work will focus on extending this approach to other film materials and deposition conditions, with the aim of further optimizing the process and broadening its applicability.

References

[1]Samco Now Technical Report, Vol. 93, April 2016

[2]Samco Now Technical Report, Vol. 118, July 2022