UV Ozone Cleaning

UV Ozone cleaning is a widely used method for preparing and cleaning surfaces in material research and device fabrication. As an alternative to oxygen plasma cleaning, it relies on a unique photochemical reaction to clean and modify surfaces with precision and efficiency.

This page explains the fundamentals, advantages, and applications of UV Ozone cleaning, as well as how Samco supports researchers and industry professionals with our advanced UV Ozone cleaning systems.

How UV Ozone Cleaning Works

The UV Ozone cleaning process utilizes photochemical reactions initiated by ultraviolet light. Several factors play a role in the effectiveness of this process:

UV Irradiation

UV lamps emit two specific wavelengths of light, 185 nm and 254 nm, each contributing to the cleaning process.

- 185 nm UV light splits molecular oxygen (O₂) into triplet atomic oxygen (O(³P)), which then reacts with molecular oxygen to generate ozone (O₃). (Fig. 1)

- 254 nm UV light breaks down ozone (O₃) into molecular oxygen (O₂) and singlet atomic oxygen (O(¹D)). (Fig. 2)

Singlet atomic oxygen is highly reactive and oxidizes inorganic surfaces such as silicon wafers. For organic materials, it breaks molecular chains, converting organic residues into volatile byproducts like CO₂, H₂O, and O₂.

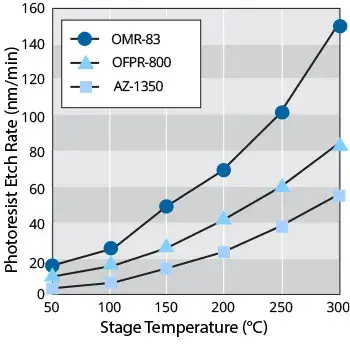

Sample Stage Temperature

The temperature of the sample stage significantly impacts the cleaning process. Singlet atomic oxygen has a short lifetime (~10 ms), and its density is a limiting factor. Heating the sample stage above 100°C enhances thermal dissociation of ozone, increasing the density of reactive species and improving cleaning efficiency.

Higher stage temperatures can also boost processes like photoresist ashing by increasing the density of atomic oxygen.

Advantages of UV Ozone Cleaning

UV Ozone cleaning offers several distinct benefits compared to other surface preparation techniques:

- Minimized substrate damage: Unlike plasma treatments, UV Ozone cleaning does not involve ion bombardment, reducing the risk of charging damage and preserving the electrical properties of sensitive devices.

- No hazardous effluents: UV Ozone cleaning is a dry process that eliminates the need for chemical waste disposal associated with wet cleaning. Samco systems include ozone decomposition units to ensure safe operation in cleanroom environments.

Supporting Research and Industry

UV Ozone cleaning is versatile, with applications across material research and device manufacturing, including:

- Surface cleaning of silicon wafers and III-V compound semiconductors (e.g., GaAs, InP)

- Lead frame and bond pad cleaning for packaging

- Surface activation and wettability improvement for materials like glass, PDMS, PMMA, COC, and COP

- Adhesion enhancement for direct substrate bonding

- Organic contamination removal and photoresist ashing/stripping

- Surface cleaning of AFM tips, QCM sensors, and SPR chips

- UV curing, hard baking, and descumming of photoresist